Hog Island Advantage

Hog Island boats hulls are manufactured differently than aluminum or fiberglass boats. We rotational mold our boat hulls. The Hog Island manufacturing process uses technologically advanced polyethylene resins, and North America's largest rotational molding oven to form one piece durable, naturally buoyant, and maintenance free boat hulls. Our high density polyethylene resin is what the world calls plastic. Ours is linear and recyclable.

Other rotational molded products you see everywhere are kayaks and canoes. The reason for this is plastic is more forgiving on impact than fiberglass or aluminum. Plain and simple plastic boats absorb collisions with hard objects better than fiberglass or aluminum boats, and plastic floats. Click here to see our video of our cut in half drift boat floating. (Tip: If you're in a hurry fast forward to 1:30 to see our boat floating in half. It's incredible in a good way.)

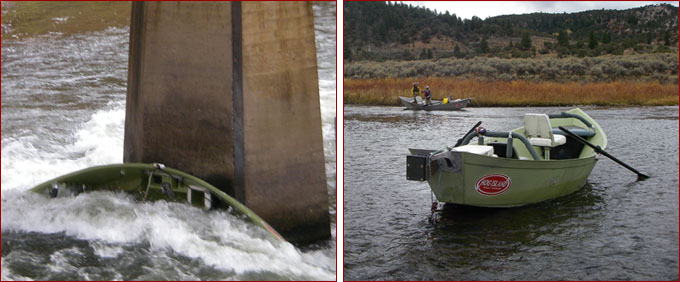

To be specific, our boat hull construction is a sandwich of high density polyethylene , known as hdp, and rigid polyethylene foam. The picture at right shows a cross section of our high density linear polyethylene skin and our rigid linear close cell foam. Since our skin and foam core are both linear polyethylene, the molecules line up, and form a strong chemical bond that gives our hull it's rigidity and strength. We believe our boats to be the World's largest commercial skin-foam-skin part. The result for Hog Island customers is a very strong boat that absorbs impact like no other hull. The picture at right shows one of our LTD 16 drift boats wrapped at the Pinball Rapid on the Upper Colorado River. Here is a link to the story of what happened. Click Here The picture below at right shows the Pinball Rapid wrapped boat two years later floating and being happy on the Colorado River. We don't know of another drift boat capable of this.